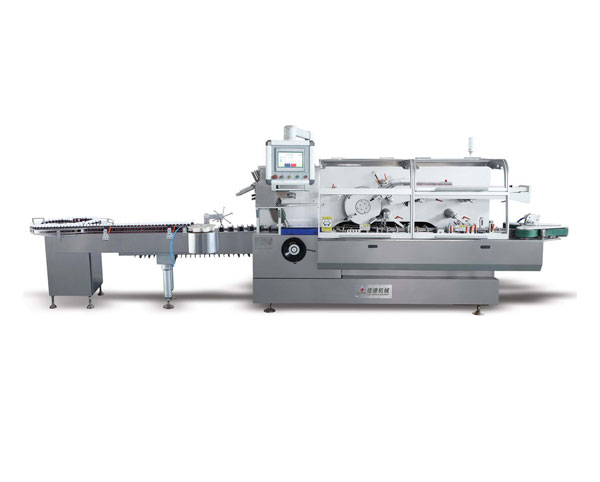

260 Cartoning machine

JDZ260LZ packing line is composed of 2 units of flowpack wrapping machine and 1 unit JDZ260 continuous motion cartoning machine. It is suitable for any kinds of flowpack type product packing and cartoning.

Process:

1. Flowwrapping: packing the items into the bag.

2. Cartoning: filling the bags into carton box.

Flowpack Wrapping machine

Main Feature:

1. Compact structure, stable and advanced performance, easy for operation.

2. Double frequency convert motor, and stepless variable speed, and the length of bag can be set on PLC, and cutting will be reaction instant, just one step, and save the time and film.

3. PLC control, friendly operate interface, for convenient and rapid to set parameters

4. Intelligence software, diagnose and show fault automatically.

5. Hi-sensitive electric eye, which trace the printed web on film and make the sealing on accurate position.

6. Accurate temperature control, which is control the sealing temperature for various of packing film. And the sealing effect is very well.

7. Main body is made in stainless steel. Fit to GMP standard.

8. Simple transmission system, which is more reliable work and convenient maintenance.

9. According to the situation of packaging products, it can be combined with different automatic feeder.

Technical data:

| Production capacity | 30-230 (package/minute) |

| Packaging size(two cutters) mm | (60-190)×(30-110)×(5-40) |

| Packaging size(one cutters) mm | (120-190)×(30-110)×(5-60) |

| Max width of film | 250mm |

| Power of supply | AC220V/ 50HZ 2.4KW |

| Weight | 700kg |

| Outline dimensions | 4050×650×1550mm |

JDZ 260 Horizontal Cartoning machine

JDZ260 is a horizontal continuous motion cartoner with balcony construction It has been specially designed for medium speed packing lines. JDZ260 has got multiple pushers to push the products into the carton in a very smooth way. It incorporates many new features like positive carton openings by rotary pick up arm to ensure the simple and positive carton transport.

It is suitable for automatic inserting ALU/PVC blister, bottle, soft tube, soft AL/AL strips and pouch into carton, also can link to blister packing machine to form production line.

Application

With high efficiency, high performance production capacity, leaflet folding and conveying, carton opening and forming, posterior pushing structure and related technology all reach Europe and USA standards; Simple design and posterior continuous pushing structure makes operation and maintenance more convenient; three equal rotation opening carton and under twice pre-forming device to ensure that carton open and form completely.This model is automatic high speed continuous cartoning machine which is high performance product incorporates pneumatic-photo-electro-mechanic.

Feature

1.International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

2.Adopt human-machine operation system.

3.Automatically displaying device for trouble, speed and finished products counting.

4.Machine running without pressing if no products or incorrect position of products. And stopping automatically if incorrect position of product into carton after return or no cartons or out of leaflets continuous.

5.No products not suction leaflet, no leaflet not suction carton.

6.Automatic detection and rejection device for lacking blister goods and leaflets.

7.Protecting automatically for overloading.

8.stable performance , easy operation.

| Item | Technical parameters | |

| Encasing speed | 260boxes/min | |

| Box | Quality requirement | 250-350g/M2[Base on carton size] |

| Dimension range(L×W×H) | (70-180)mm×(35-80)mm×(14-50)mm | |

| Leaflet | Quality requirement | 60-70g/M2 |

| Unfolded leaflet specification(L×W) | (80-250)mm×(90-170)mm | |

| Fold range(L×W) | [1-4]Fold | |

| Compressed air | Working pressure | ≥0.6mpa |

| Air consumption | 160-200L/min | |

| Power supply | 380V 50HZ | |

| Motor power | 5kw | |

| Machine dimension(L×W×H) | 4800mm×1600mm×1860mm | |

| Machine weight | 3000kg | |